Workover rigs are specialized drilling rigs used to repair, maintain, or enhance the productivity of existing oil and gas wells. Unlike exploration or development drilling rigs, which drill new wells, workover rigs are designed for interventions on already producing or shut-in wells. Below is a detailed explanation of their functions, types, and key components.

Well Repair: Fixing issues such as casing leaks, damaged wellbore equipment, or mechanical failures.

Tubing Replacement: Pulling and replacing production tubing or downhole tools.

Well Stimulation: Performing acidizing or hydraulic fracturing to boost production.

Water/Gas Shut-off: Isolating unwanted water or gas zones to improve hydrocarbon recovery.

Recompletion: Changing the production zone or completing the well in a new formation.

Platform Workover Rigs: Used on fixed offshore platforms for well intervention.

Land Workover Rigs: Mounted on trucks or trailers for easy mobilization on land.

Skid-Mounted Rigs: Compact units for confined spaces or remote locations.

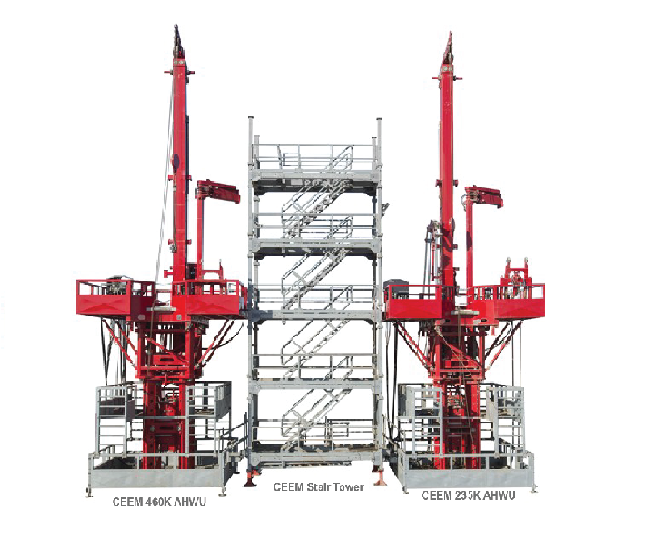

Hydraulic Workover Units (HWUs): Use hydraulic systems for lighter interventions.

Mast: The vertical structure that supports lifting operations.

Hoisting System: Includes a winch, wire ropes, and a hook for handling pipes.

Rotary Table: Rotates drill strings or tubing during workover operations.

Mud Pumps: Circulate drilling fluid to clean the wellbore if needed.

Blowout Preventer (BOP): A safety device to control well pressure.

Cost-Effective: Cheaper than drilling a new well.

Faster Operations: Quicker mobilization and execution compared to drilling rigs.

Versatility: Capable of performing various well intervention tasks.

Extended Well Life: Enhances production and recovers more hydrocarbons.

Depth Limitations: Some rigs are not suitable for ultra-deep wells.

Safety Risks: Potential blowouts, equipment failures, or chemical exposure.

Well Condition Dependence: Severely damaged wells may require complex solutions.

Smaller Size: Workover rigs are more compact and lightweight.

Lower Power: Not designed for drilling new wells but for maintenance.

Mobility: Many workover rigs are easily transportable between wells.

Sayma Company, with its highly experienced international team, is capable of providing customized solutions tailored to your workover project requirements. We specialize in supplying workover rigs and related equipment that fully comply with API standards, ensuring safety, efficiency, and reliability in all well intervention operations.

With our expertise, we deliver end-to-end workover solutions, from engineering and equipment procurement to onsite execution, meeting the highest industry standards.

The American Petroleum Institute (API) provides key standards for well workover, servicing, and intervention operations. These standards cover technical requirements, safety protocols, and best practices for maintaining and repairing oil and gas wells. Below are the most critical API standards related to workover operations:

“Recommended Practice for Drill Stem Design and Operating Limits”

Covers design and operational limits for drill strings and workover equipment.

“Recommended Practice for Care and Use of Casing and Tubing”

Guidelines for handling casing and production tubing during workover operations.

“Recommended Practice for Testing Well Cements”

Testing procedures for cement integrity after well repairs.

“Recommended Practice for Well Control Operations”

Well control procedures to prevent blowouts during workover.

“Recommended Practice for Occupational Safety for Oil and Gas Well Drilling and Servicing Operations”

Safety requirements for drilling and well servicing (including workover).

“Recommended Practice for Well Control During Workover and Completion Operations”

Well control best practices during workover and recompletion.

“Classification of Locations for Electrical Installations at Petroleum Facilities”

Electrical safety standards for hazardous zones in well servicing.

“Specification for Drilling and Well Servicing Structures”

Technical specs for workover rigs and drilling structures.

“Specification for Wellhead and Christmas Tree Equipment”

Standards for wellhead and production tree equipment used in workovers.

“Specification for Rotary Drill Stem Elements”

Requirements for rotary drilling equipment in workover operations.

“Specification for Drilling and Production Hoisting Equipment”

Standards for hoisting systems in workover rigs.

“Specification for Drill-through Equipment”

BOP (Blowout Preventer) and well control equipment for workovers.

“Recommended Practice for Evaluation of Casing and Tubing Connections”

Testing procedures for casing and tubing connections.

“Recommended Practice for Testing of Wellhead Equipment”

Testing requirements for wellhead components after workover.

“Risk-Based Inspection”

Risk assessment and inspection guidelines for workover equipment.

“Operation and Maintenance of Offshore Cranes”

Guidelines for crane operations on offshore workover rigs.

“Remotely Operated Tools and Interfaces on Subsea Production Systems”

Standards for subsea well intervention and workover.

User comments